Warner Electric has provided magnetic headsets to many fine OEMs and users in the capping industry for over 20 years. Featuring smooth torque magnetic technology to provide the most consistent torque control on the market.

From capping carbonated soft drinks, bottled water, milk and juice, to ketchup, salad dressings, personal care products, and motor oil, reliable Warner Electric capping headsets, chucks, and anti-rotation knives have successfully improved the overall performance of capping operations around the world.

Warner Electric magnetic headsets feature constant smooth torque technology; differing with most competitor OEM headsets that have two opposing magnets causing pulsating torque. It’s the pounding effect of a pulsating clutch that increases cap tightness and torque variability during the capping process.

Success story in application

Vodka Manufacturer turns to Warner Electric for capping process improvement

A vodka manufacturer participated the World Spirits Competition

in San Francisco, which ended up earning the double gold medal and

the unanimous judges’ choice, beating out 72 vodkas from around the

world, including flavored vodkas. After that, their handmade vodka has grown substantially, from producing 1,000 cases in 1997 to more than 200,000 cases per year.

Customer‘s Problem:

The copper finish coating of their caps was being damaged in the capping process as the coating is somewhat delicate in nature. The chucks need to contact the closure in a way that holds the cap firmly without damaging it. To make matters worse, the existing headsets required parts that were expensive and difficult to find.

Solution of Warner Electric

Warner Electric provides magnetic capping headsets feature smooth torque magnetic technology. These headsets demonstrate improved performance over the traditional synchronous OEM headsets by eliminating pulsing, vibration, and pounding. It well eliminated damage to the closures during application, and bottles were no longer getting through the machine without a cap being installed.

Conclusion:

Warner Electric headsets and chucks perform

reliably, without damaging the special copper

finish coating used on caps.

The manufacturer is extremely satisfied with the results. Jamming problems and the need for maintenance during shifts were eliminated once the Warner Electric headsets were installed.

The original headsets would not run for more than a few minutes before having issues, needing adjustments or cleaning.

Smoother torque puts a new twist on bottle capping at a soda plant

The customer’s problem:

- Smaller caps are over-tightened, making it difficult to loosen the caps.

- The sudden increase in torque has a great impact on the equipment, and it is necessary to modify or replace the capping head every three to four months

- The capping head will rust after only 10 weeks

Solution of Warner Electric

- Warner magnetic capping headsets applies torque smoothly and consistently. This eliminates overtightening and reduces the variation in the amount of torque needed to unscrew the cap.

- have a visual scale on the side for setting torque, making changeovers easier and faster. They need no torque measurements, recalibration, or trial-and-error operator judgment.

- Warner’s steel headsets come with a quad seal and drain holes, resisting ozone.

Why Customers Choose Warner Electric

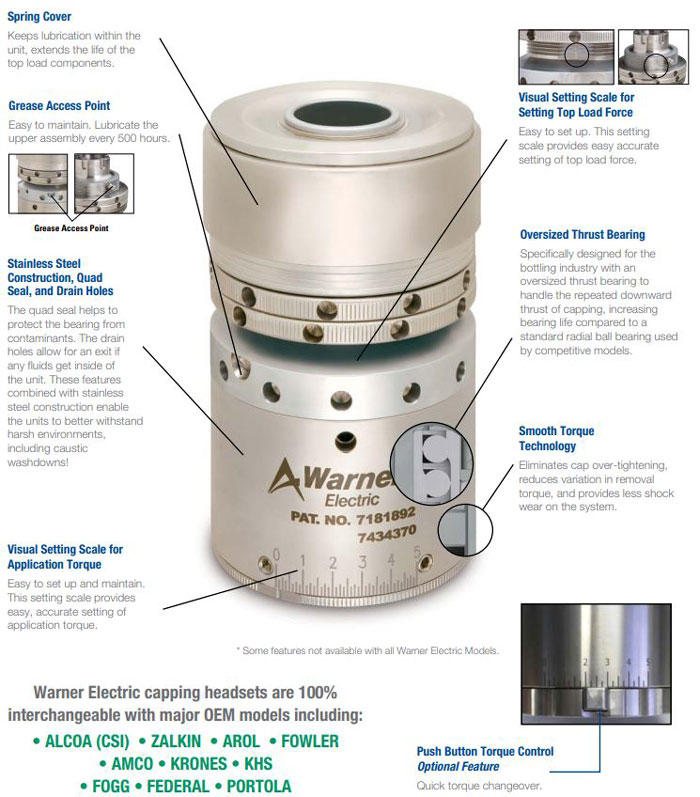

100% Interchangeable with major OEM headsets No machine modification is required !...

(Alcoa [CSI], Zalkin, AROL, Fowler, Fogg, Federal, Portola, AMCO, Krones, KHS, and others)

Smooth Torque: Constant torque eliminates torque pulsations that cause cap over-tightening and provides less shock wear on machine components

Improved Efficiency: Smooth torque provides less variation in removal torque, improving end-product quality & consistency

Longer Operation Life and Lower Cost of Ownership: Lower cost for new units & product design enables longer operating life than OEM headsets, enabling lower rebuild cost with fewer rebuilds

Easy to Set-up and Maintain: Visual setting scales for top load force and application torque

Excellent Service Expertise and Delivery Service technician expertise capping machinery; single units ship within 2 days, 2-4 weeks for entire machine

WARNER ELECTRIC’S UNIQUE PRODUCT DESIGN

ENABLES LONGER LIFE FOR YOUR MAGNETIC HEADSET