Warner Electric is the important electromagnetic clutch & brake division of Altra Motion, including the brands Warner Electric, Matrix, AO LI XI…, are world leaders in the development of innovative electromagnetic clutch & brake solutions. They offer a full range of brakes, which can be specialized in customized solutions to meet specific performance and installation requirements in robotic markets. Warner’s braking solutions are designed with the industry’s toughest challenges in mind, utilizing proprietary technology to analyze magnetic properties of the brake, brake interfaces and surroundings.

1 - Matrix SMB brake

Matrix, a leader in advanced servo motor braking solutions, has designed a range of standard spring-applied brakes, specific to servo motor applications. Matrix SMB brakes are available in a range of sizes compatible with most common servo motor frame sizes.

Features:

- Standard brake sizes compatible with most common servo motor frame sizes

- Unique proprietary friction material

- Reduced lead time

- Optimal performance-to-size ratio

Available on request*:

1EB Brakes

- Hub options

- Alternative mounting configurations

- Bearing and encoder recess

- Connector options

- Lead wire options

- Application representative testing

- Application specific dynamic torque ratings

2 - Matrix 1EB brake

Matrix engineers developed various sizes of modified spring-applied, electromagnetically released 1EB Series servo motor brakes.

Features:

XS Brakes

- Custom spring-applied, electrically released brakes

- Power-off holding and stopping functionality

- Low inertia/high torque

- Low backlash

- Special plating and friction materials

3 - XS Brake

WR Brakes

XS Brakes have been designed with two key constraints in mind: optimize the torque level in the smallest space design and at the lightest weight. No compromises have been made between the performance of the brake, the extra low weight, and the required space envelope to fit this brake in your application. XS Brakes are highly reliable, fail safe devices designed as statically engaged/disengaged holding brakes. These brakes provide low cycle rate stopping action in emergency situations.

4 - WR Brake

Warner Electric Spring Applied Electrical Released WR Brakes are Highly reliable, built-in-flexible design for static engagement with some emergencies stop capability.

Features:

AO LI XI 4G Brakes

- Extremely compact design

- Intended for use in static applications

- Various mounting plates available

- RoHS compliance

5 - AO LI XI 4G Brake

AO LI XI 4G series Thin Brakes has newly been launched by Altra Industrial Motion (Shenzhen) Co., Ltd., which takes "thin" and "light" as its product design elements and highlights.

Features:

- The thickness of 4G series brake is as low as 12mm.

- The smallest brake weight only 30g.

- Dual voltage control: 24v-7v.

- Temperature range: 0 - 100 ° C.

- A small number of dynamic emergency stops can be sustained.

- Working duty: S1 - 100%.

- Low heat dissipation.

- Large middle bore (larger motor shaft diameter is acceptable).

- There are 7 models. The shaft sleeve can pass through the brake bore on 7 models, which is more convenient for installation

Success stories in Robotic Application

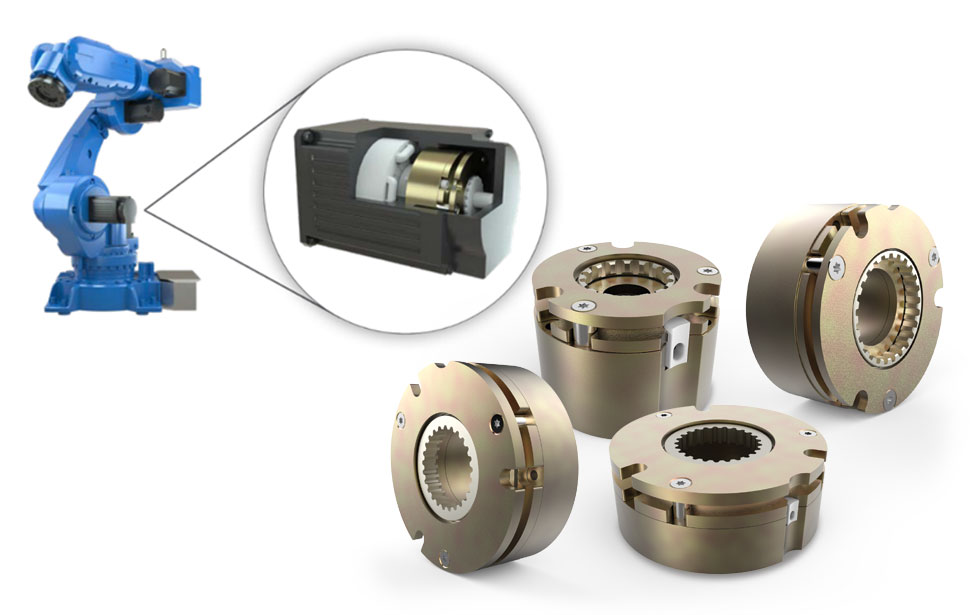

Warner Electric XS & WR Brakes Reduce Six-Axis Robot Footprint

Six-axis robots have become the standard solution for automated assembly tasks due to their ability to carry out complex maneuvers. As they have grown in popularity, robot OEMs have strived to reduce the size and mass of their six-axis designs to promote space efficiency and productivity.

A stepping motor manufacturer located in Germany needed braking solutions for use on 6-axis industrial robots. The brakes are mounted directly to the back of the various electric stepper motors to provide static holding of the robot arm in the precise positions required for small component assembly. The motor OEM contacted Warner Electric based on its reputation for superior braking application knowledge and advanced braking technologies. Warner engineers, working closely with the OEM’s team, recommended an XSB X-Small electrically-released, spring-set brake for installation on the very small 6th axis motor that rotates the tip of the robot’s arm. The Model XSB33S supplied weighed only 90 g with a torque rating of 35 Ncm. The compact brake is smaller than competitor models and was modified for reduced noise to meet the customers acceptable levels. All units feature a customized adaptor flange to accomodate individual customer-specific mounting requirements. The brakes provide low cycle rate stopping action in emergency situations.

Extremely compact Model WR220 and WR225 spring-applied, electrically-released brakes were supplied for use on the robot’s 5 other axis motors. These highly reliable models are specifically designed as statically engaged/disengaged holding brakes.

Warner Electric product design and development, manufacturing and service are of the highest standard. Our refined in-house manufacturing processes and first-rate supply chain partners help us produce product quality to meet or exceed customer expectations. Component traceability from supplier to assembly and 100% end-of-line inspection record-keeping across the range eliminates defective product before reaching the customer.

OEMs around the world have come to rely on Warner Electric’s braking application knowledge and successful experience with the lighter, smaller, and thinner products to meet the faster speeds and precision accuracy requirements in a wide range of robotic application.

XS Brake

WR Brakes